CNC Machining Service: Your Trusted CNC Turning Parts Factory

In the modern manufacturing landscape, the demand for precision and efficiency has led to the rapid evolution of machining technologies. Among these advancements, CNC machining services have emerged as a pivotal solution, especially in the realm of CNC turning parts. At deepmould.net, we pride ourselves on being a leading CNC machining service provider, offering top-tier capabilities to meet your specific needs.

Understanding CNC Machining Services

CNC machining, or Computer Numerical Control machining, refers to the automated control of machining tools by means of a computer. This technology encompasses various operations, such as milling, turning, and grinding, to create complex parts from a wide range of materials, including metals, plastics, and composites.

The Benefits of CNC Machining

- Precision and Accuracy: CNC machining can produce parts with intricate details and tight tolerances, often up to ±0.001 inches. This precision is crucial for industries where specifications are critical.

- Consistency: Once a CNC program is set, it can produce identical parts consistently, reducing variability and enhancing quality.

- Efficiency: CNC machines can operate continuously, leading to increased production rates and reduced manufacturing lead times.

- Versatility: CNC machining services can accommodate a wide range of materials and complexities, making it suitable for various applications.

Why Choose a CNC Turning Parts Factory?

CNC turning is a specific type of CNC machining that focuses on rotating a workpiece against a cutting tool. This method is particularly effective for manufacturing cylindrical, spherical, or conical parts. Here are several reasons to partner with a professional CNC turning parts factory:

Expertise in Design and Production

Choosing a specialized factory ensures that you have access to skilled engineers and machinists who understand the intricacies of CNC programming and machining. Their expertise can help you optimize designs for better manufacturability, which can significantly reduce costs and lead times.

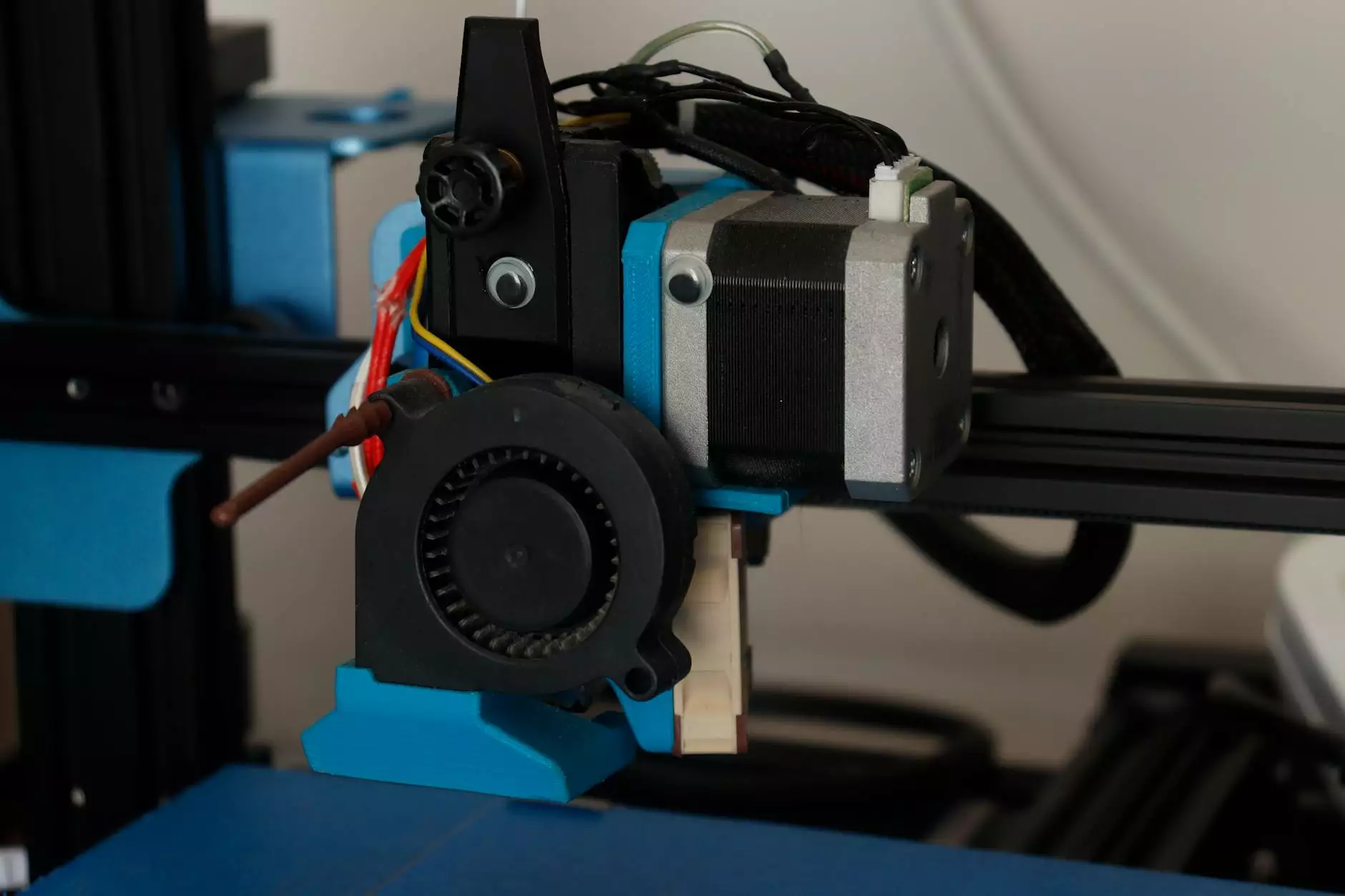

State-of-the-Art Equipment

An advanced CNC turning parts factory utilizes the latest machining technologies and equipment, ensuring that all production processes are modern, efficient, and accurate. These machines are programmably adjustable, adapting to varying part designs as necessary.

Quality Control Systems

Reputable factories implement rigorous quality control systems. Parts are inspected throughout the manufacturing process, ensuring that every component meets required specifications before it reaches your hands.

Applications of CNC Turning Parts

The applications of CNC turning parts are vast, spanning multiple industries. Here are some prevalent uses:

- Aerospace: Manufacturing components like landing gear and brackets that require high precision and reliability.

- Automotive: Producing parts such as shafts, gears, and housings that must fit together perfectly in complex assemblies.

- Medical: Creating custom surgical instruments and implants that require stringent hygienic and material standards.

- Electronics: Crafting enclosures and connectors that enable effective device functionality.

Cost-Effective CNC Machining Solutions

With the increasing pressure on manufacturing costs, businesses are on the lookout for cost-effective solutions without compromising quality. Partnering with a reliable CNC turning parts factory allows you to benefit from economies of scale. Here’s how:

1. Bulk Production Capability

Factories that specialize in CNC machining can facilitate bulk production at reduced costs. By producing large quantities of parts, the fixed costs associated with setup and programming can be spread over more items, lowering the overall cost per part.

2. Reduced Waste

Advanced CNC technologies often include software that optimizes material usage. By maximizing every square inch of raw material, a professional factory minimizes waste, translating to cost savings for clients.

How to Select the Right CNC Machining Service

When searching for a CNC machining service, consider the following factors:

1. Company Reputation

Check reviews, testimonials, and case studies to gauge the company’s reputation. A reliable factory like Deep Mould has a proven track record of delivering high-quality products on time.

2. Capabilities and Equipment

Ensure the factory has the necessary machinery and technology to meet your specific requirements. Ask about the variety of materials they work with and the range of tolerances they can achieve.

3. Customer Support

The level of customer support can significantly impact your experience. Choose a factory that offers comprehensive assistance throughout the production process, from initial consultation to after-sales service.

Environmental Responsibility in CNC Machining

As industries become more aware of their environmental footprints, many CNC machining services adopt sustainable practices. Here’s how a CNC turning parts factory can operate responsibly:

- Material Recycling: Efficient factories use recycling programs to repurpose waste materials, reducing environmental impact.

- Energy Efficiency: Cutting-edge equipment is designed to minimize energy consumption during operation.

- Pollution Control: Advanced cleaning and filtration systems help manage airborne particulates and harmful emissions.

Conclusion

Choosing the right CNC machining service and CNC turning parts factory is crucial for the success of your manufacturing projects. With the advantages of precision, consistency, and cost-effectiveness, partnering with a reliable provider like Deep Mould can transform your production capabilities. As the manufacturing landscape continues to evolve, stay ahead of the competition by embracing the unrivaled benefits of CNC machining services.

cnc machining service cnc turning parts factory